Precision and Efficiency: Exploring the 32 Cavity Hot Runner PET Preform Mould

2023-10-18

Introduction:

PET (Polyethylene Terephthalate) preforms are widely used in the beverage industry for the production of bottles and containers. The quality and consistency of PET preforms play a crucial role in ensuring the integrity and aesthetics of the final product. In this blog, we will delve into the world of the 32 Cavity Hot Runner PET Preform Mould, exploring its features, benefits, and how it contributes to the efficient and high-volume production of PET preforms.

1. Understanding PET Preform Moulds:

PET preform moulds are precision tools used in the injection molding process to create preforms, which are then stretched and blown into bottles. These molds are designed to shape molten PET material into the desired preform shape, ensuring accuracy, consistency, and reproducibility.

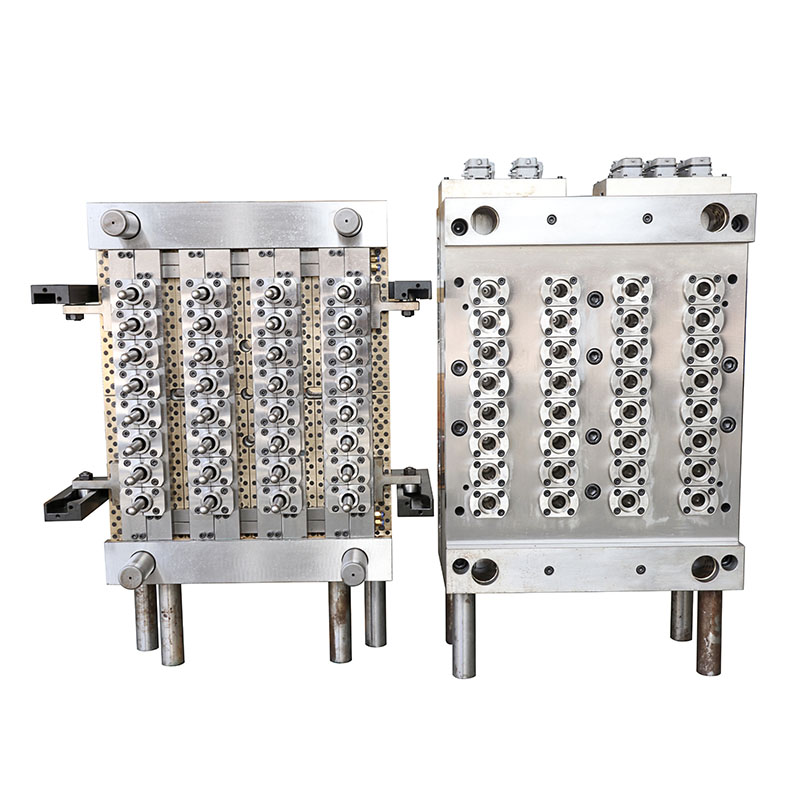

2. 32 Cavity Hot Runner PET Preform Mould:

The 32 Cavity Hot Runner PET Preform Mould is a specific mold configuration that allows for the simultaneous production of 32 preforms in a single molding cycle. This high-cavity mold design is favored for its ability to achieve high production volumes while maintaining accuracy and quality.

3. High Efficiency and Productivity:

The 32 Cavity Hot Runner PET Preform Mould offers exceptional efficiency and productivity. With 32 cavities, it enables the production of a large number of preforms in each molding cycle, significantly increasing output compared to molds with fewer cavities. This increased productivity translates into faster production cycles, reduced manufacturing costs, and improved overall efficiency.

4. Hot Runner System:

The hot runner system is a key feature of the 32 Cavity Hot Runner PET Preform Mould. It consists of a series of heated channels that deliver molten PET material directly to each cavity, ensuring uniform filling and optimal material flow. The hot runner system minimizes material waste, reduces cycle time, and eliminates the need for trimming or post-molding operations, further enhancing productivity and cost-effectiveness.

5. Precision and Consistency:

PET preforms require precise dimensions and consistency to ensure they fit properly in bottle molds and provide optimal performance. The 32 Cavity Hot Runner PET Preform Mould is designed with meticulous attention to detail, ensuring uniform wall thickness, accurate weight distribution, and consistent preform dimensions across all cavities. This precision ensures that the final bottles are structurally sound and visually appealing.

6. Durable and Reliable:

The 32 Cavity Hot Runner PET Preform Mould is constructed with high-quality materials and undergoes rigorous manufacturing processes to ensure durability and longevity. The mold is engineered to withstand the demanding conditions of high-volume production, including high temperatures and continuous use. This durability reduces maintenance requirements and ensures the mold's reliability and performance over an extended period.

Conclusion:

The 32 Cavity Hot Runner PET Preform Mould is a highly efficient and reliable tool for the production of PET preforms. Its high-cavity design, coupled with the hot runner system, enables the production of a large number of preforms with precision, consistency, and speed. This mold configuration not only enhances productivity but also contributes to cost savings, improved quality, and streamlined manufacturing processes. Investing in a 32 Cavity Hot Runner PET Preform Mould ensures that your production facility can meet the demands of high-volume PET preform manufacturing. By utilizing this advanced molding technology, you can optimize production efficiency, maintain consistent product quality, and stay ahead in the competitive beverage industry.