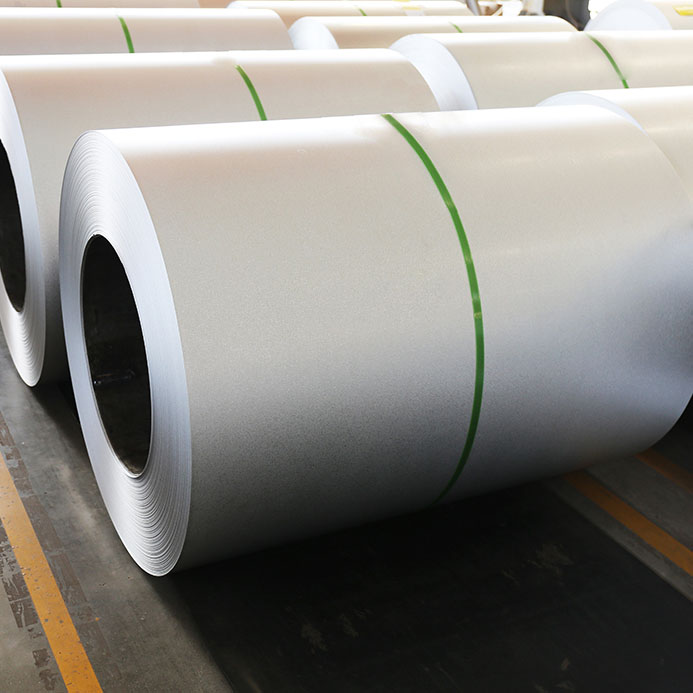

Beyond the Surface: Testing and Quality Control Measures for Enduring Color-Coated Galvanized Steel Coils

2023-11-27

Introduction:

The reliability and longevity of color-coated galvanized steel coils hinge not only on their visual appeal but also on rigorous testing and quality control measures. In the intricate dance of durability and aesthetics, these measures serve as guardians, ensuring that the final product not only looks impressive but stands resilient against the tests of time. In this blog, we'll explore the testing and quality control processes typically employed to guarantee the reliability and longevity of color-coated galvanized steel coils.

1. Adhesion Testing:

Objective:

Ensuring that the color coating adheres uniformly to the galvanized steel substrate.

Process:

Various methods, such as cross-cut or pull-off tests, are conducted to evaluate the adhesion strength of the color coating.

2. Thickness Measurement:

Objective:

Verifying that the color coating has the specified thickness for optimal protection.

Process:

Techniques like magnetic induction or eddy current methods are employed to measure the thickness of the coating.

3. Impact Resistance Testing:

Objective:

Assessing the ability of the color-coated steel to withstand impact without compromising its integrity.

Process:

Impact resistance tests involve subjecting the coated steel to controlled impacts and evaluating any resulting damage.

4. Flexibility and Bend Tests:

Objective:

Ensuring that the color coating maintains flexibility and adhesion during bending or forming processes.

Process:

The coated steel is subjected to bending or forming, and the coating's performance is assessed for cracks, delamination, or other defects.

5. Corrosion Resistance Testing:

Objective:

Confirming the ability of the galvanized and color coating to protect the steel from corrosion.

Process:

Salt spray testing, cyclic corrosion testing, or exposure to harsh environmental conditions are conducted to simulate real-world corrosion challenges.

6. Color Consistency Testing:

Objective:

Verifying that the color-coated steel maintains consistency in color and appearance.

Process:

Spectrophotometers and colorimeters are used to measure and compare color consistency across the entire coil.

7. UV Resistance Testing:

Objective:

Assessing the color coating's ability to withstand prolonged exposure to ultraviolet (UV) radiation without fading or degradation.

Process:

UV accelerated weathering tests replicate long-term exposure to sunlight and assess the coating's resistance to UV-induced degradation.

8. Humidity and Heat Resistance Testing:

Objective:

Evaluating the performance of the color-coated steel under high humidity and elevated temperatures.

Process:

Coated samples are subjected to controlled humidity and temperature conditions to assess their resistance to environmental stress.

Conclusion:

The reliability and longevity of color-coated galvanized steel coils are not left to chance; they are meticulously verified through a battery of testing and quality control measures. From adhesion and impact resistance to corrosion protection and color consistency, each test contributes to the assurance that these coils will not only endure the elements but also retain their aesthetic appeal over time. As industries continue to prioritize quality and sustainability, the robust testing and quality control processes surrounding color-coated galvanized steel coils ensure that they stand as exemplars of both performance and longevity.