Boosting Efficiency with the Automatic Capping Machine

2025-02-28

In the world of packaging, consistency and speed are crucial for maintaining product quality and meeting production demands. One of the essential machines that help achieve these goals in industries ranging from food and beverages to pharmaceuticals and cosmetics is the automatic capping machine. This piece of equipment plays a vital role in the final stage of the packaging process by securely sealing containers with caps, ensuring product integrity, safety, and convenience for consumers.

What is an Automatic Capping Machine?

An automatic capping machine is a fully automated system designed to place and securely seal caps onto bottles, jars, or containers. These machines are used in mass production lines where speed, precision, and consistency are key. Automatic capping machines are capable of handling a variety of cap types, including screw caps, snap-on caps, and press-on caps, depending on the needs of the production line.

How Does It Work?

The automatic capping machine operates through a series of steps to ensure the efficient application of caps:

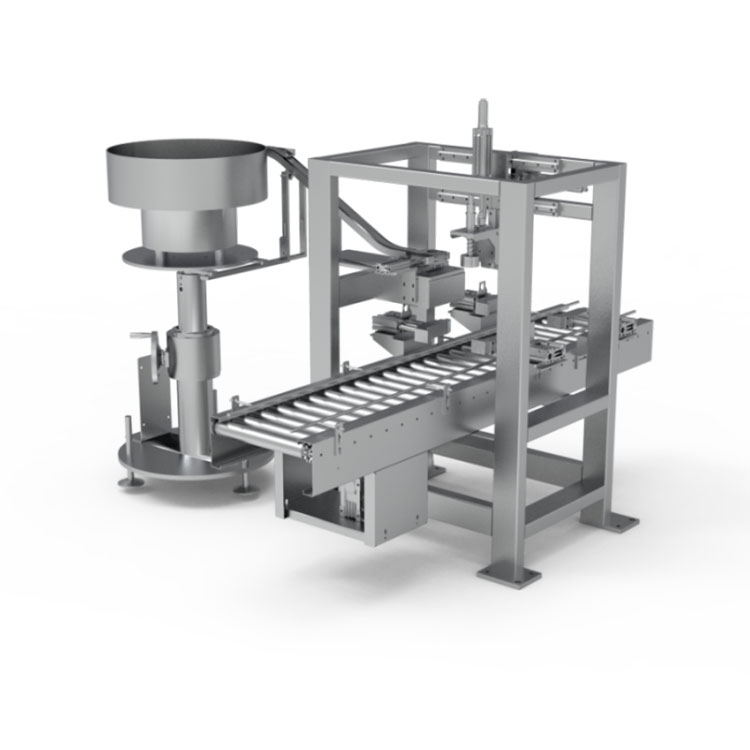

1. Feeding the Containers: The containers or bottles are fed into the capping machine via a conveyor belt, moving them into position for capping.

2. Cap Placement: The machine uses a hopper or cap feeder to automatically feed caps into the capping station. Depending on the design, the machine may use mechanical arms, vibratory systems, or rotary devices to place the cap correctly onto each container.

3. Capping Process: Once the cap is in place, the machine applies a predefined amount of torque to securely seal the cap onto the container. This can involve various techniques, such as screw capping, pressing, or snapping, depending on the cap design and product requirements.

4. Discharge: After the cap is securely sealed, the containers are discharged onto another conveyor belt, ready for labeling, packaging, or shipping.

Key Features of an Automatic Capping Machine:

1. High-Speed Operation: Automatic capping machines are designed for high-speed operations, capable of sealing thousands of containers per hour. This ensures that production lines run smoothly and efficiently, meeting high demand without sacrificing quality.

2. Precision and Accuracy: These machines offer precise capping torque control, ensuring that each container is sealed with the correct amount of pressure. This is crucial for maintaining product safety, preventing leaks, and ensuring proper sealing of containers to avoid contamination.

3. Versatility: Automatic capping machines can handle a variety of container sizes and cap types, including bottles, jars, and tubes with screw-on, snap-on, or press-on caps. This makes them highly adaptable to different industries and products.

4. Minimal Manual Labor: Once set up, the automatic capping machine requires little to no human intervention, reducing the need for manual labor and increasing overall efficiency. This not only lowers labor costs but also helps maintain a safer work environment.

5. Reduced Risk of Errors: By automating the capping process, the risk of human error is significantly reduced, leading to fewer defective or improperly sealed products. This enhances product quality and ensures consumer safety.

6. Easy Integration into Production Lines: Automatic capping machines can be seamlessly integrated into existing packaging lines. They are typically designed to work alongside other machinery, such as fillers and labelers, to create a streamlined, fully automated production process.

Benefits of Using an Automatic Capping Machine:

1. Increased Productivity: With its ability to cap large quantities of containers in a short time, the automatic capping machine helps increase production output and reduce bottlenecks in the packaging process.

2. Enhanced Consistency and Quality Control: By applying consistent capping pressure and ensuring the correct placement of caps, the machine minimizes product defects, ensuring a higher level of quality and uniformity.

3. Cost Savings: While the initial investment may be significant, the long-term cost savings are notable. Fewer labor costs, reduced waste, and increased throughput make automatic capping machines an excellent investment for high-volume production lines.

4. Improved Safety: Properly sealed containers reduce the risk of product contamination or spoilage. This is particularly important in industries like food and pharmaceuticals, where safety and hygiene are top priorities.

5. Flexibility and Adaptability: The ability to switch between different cap types and sizes with minimal adjustments makes automatic capping machines flexible and adaptable to varying production needs.

Applications of Automatic Capping Machines:

Automatic capping machines are widely used across numerous industries, including:

- Food and Beverage Industry: Used for sealing bottles, jars, and containers of sauces, beverages, oils, and other products.

- Pharmaceuticals: Ensures that medication bottles, vials, and other pharmaceutical containers are properly sealed to prevent contamination and ensure safety.

- Cosmetics and Personal Care: Ideal for sealing bottles of lotions, creams, shampoos, and other personal care products, maintaining product integrity and hygiene.

- Chemicals: Used for sealing containers that hold various chemicals, ensuring secure packaging and minimizing the risk of leaks or spills.

The automatic capping machine is a vital component in modern packaging lines, offering efficiency, precision, and versatility. By automating the capping process, it not only speeds up production but also enhances product quality, safety, and consistency. With the growing demand for high-volume manufacturing, the automatic capping machine is indispensable for industries such as food and beverages, pharmaceuticals, and cosmetics, providing businesses with a reliable, cost-effective solution for their packaging needs.