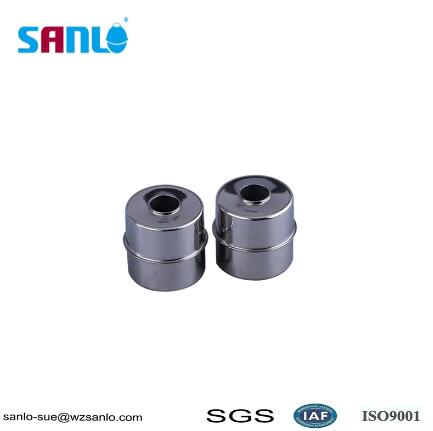

Installation and Maintenance Tips for 0.9-Inch Magnetic Float Balls

2024-07-19

Introduction

0.9-inch magnetic float balls are crucial components in various liquid level measurement systems. To ensure accurate readings and reliable performance, proper installation and maintenance are essential. In this blog, we will provide valuable tips for installing and maintaining 0.9-inch magnetic float balls, helping you achieve optimal results in your applications.

Installation Tips

1. Choose the Right Location

- Ensure the float ball has enough space to move freely without any obstructions.

- Place the float ball in a location where it can accurately reflect the liquid level without interference from turbulence or flow patterns.

2. Proper Mounting

- Use appropriate mounting hardware and brackets to secure the float ball in place.

- Ensure that the float ball is positioned vertically and aligned correctly with the sensor system to provide accurate readings.

3. Sensor Calibration

- Calibrate the sensor system according to the manufacturer's instructions to ensure precise measurements.

- Regularly check and recalibrate the sensors to account for any changes in the system or environment.

4. Check for Compatibility

- Verify that the float ball material is compatible with the liquid being measured. This prevents degradation and ensures long-term performance.

- Ensure that the float ball's magnetic strength matches the sensor's requirements for accurate signal transmission.

5. Avoid Turbulence and Foam

- Install baffles or stilling wells to minimize turbulence and foam, which can affect the float ball's movement and accuracy.

- Ensure that the float ball is installed in a calm area of the tank to provide stable and reliable readings.

Maintenance Tips

1. Regular Inspection

- Periodically inspect the float ball and the entire measurement system for signs of wear, damage, or debris accumulation.

- Check for any physical damage to the float ball, such as dents or cracks, that could affect its buoyancy and accuracy.

2. Cleaning

- Clean the float ball and the surrounding area regularly to remove any buildup of dirt, algae, or other contaminants.

- Use appropriate cleaning solutions that are safe for the float ball material and the liquid being measured.

3. Preventive Maintenance

- Schedule regular preventive maintenance to ensure the float ball and sensor system are functioning correctly.

- Replace any worn or damaged parts promptly to avoid disruptions in the measurement system.

4. Monitor System Performance

- Continuously monitor the performance of the liquid level measurement system to detect any anomalies or deviations.

- Use data logging and analysis tools to track trends and identify potential issues before they become critical.

5. Spare Parts Availability

- Keep spare float balls and other essential components on hand to minimize downtime in case of damage or failure.

- Ensure that spare parts are stored properly to prevent damage and ensure they are ready for use when needed.

Troubleshooting Common Issues

1. Inaccurate Readings

- Check for obstructions or debris that may be affecting the float ball's movement.

- Recalibrate the sensor system to ensure accurate measurements.

2. Float Ball Sticking

- Inspect the float ball and the surrounding area for any buildup of contaminants that may be causing it to stick.

- Clean and lubricate the float ball and mounting hardware if necessary.

3. Sensor Malfunction

- Verify that the sensor is properly calibrated and aligned with the float ball.

- Check for any electrical or mechanical issues with the sensor and address them promptly.

4. Liquid Compatibility Issues

- Ensure that the float ball material is compatible with the liquid being measured to prevent degradation and failure.

- Replace the float ball with a suitable material if compatibility issues are identified.

Conclusion

Proper installation and maintenance of 0.9-inch magnetic float balls are essential for ensuring accurate liquid level measurements and reliable system performance. By following these tips, you can maximize the efficiency and longevity of your measurement system. Regular inspection, cleaning, and preventive maintenance are key to preventing issues and ensuring consistent, accurate readings in your applications. Whether you are using float balls in industrial processes, HVAC systems, or other applications, these best practices will help you achieve optimal results and maintain a reliable liquid level measurement system.