Maintaining Excellence: Essential Procedures to Keep Your Extrusion Line Running Smoothly

2024-04-01

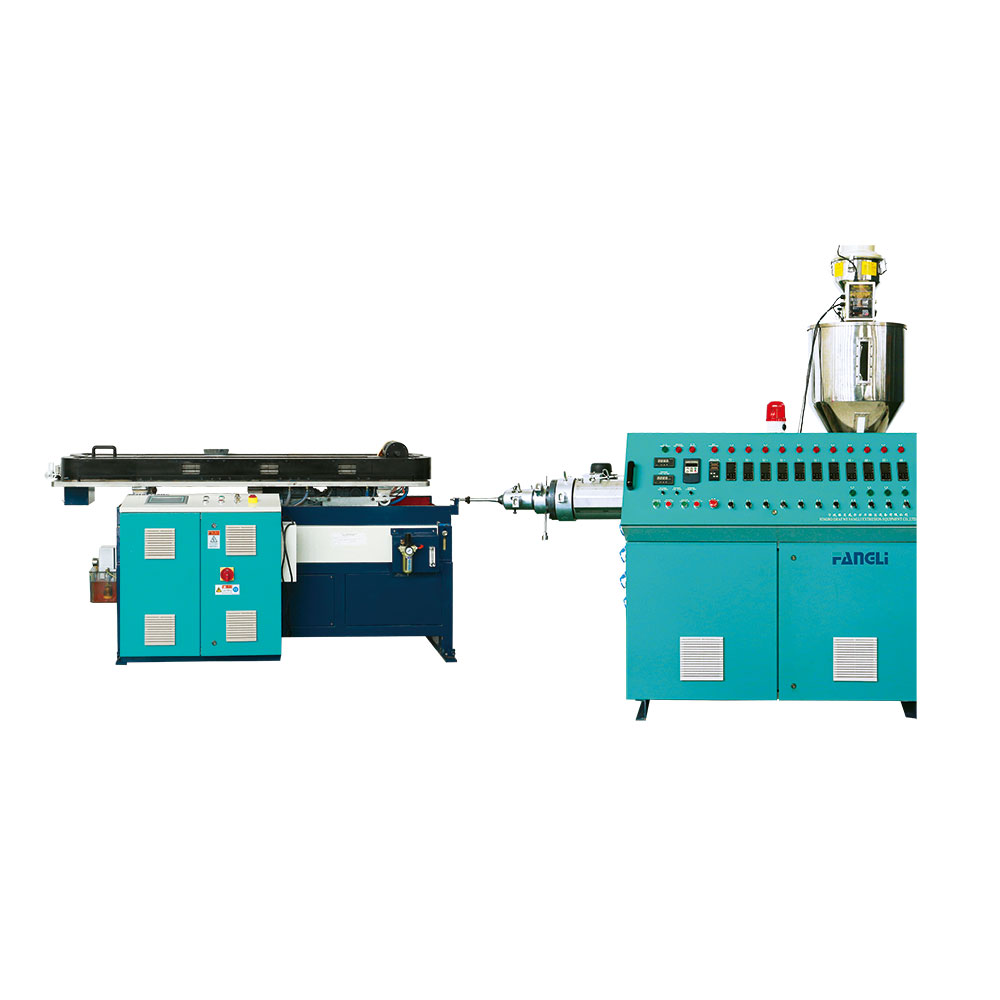

In the fast-paced world of industrial manufacturing, the reliability and efficiency of single wall corrugated extrusion lines are essential for meeting production demands and ensuring product quality. To achieve optimal performance and longevity, regular maintenance procedures are indispensable. In this blog, we'll delve into the key maintenance procedures required to keep your extrusion line running smoothly, ensuring consistent operation and minimizing downtime.

Routine Cleaning and Lubrication

Routine cleaning and lubrication are fundamental maintenance procedures that help prevent buildup of debris, residue, and contaminants on critical components of the extrusion line. Regularly scheduled cleaning sessions, using appropriate cleaning agents and methods, ensure that extruders, die heads, cooling systems, and other components remain free from obstruction and operate smoothly. Additionally, proper lubrication of moving parts reduces friction, wear, and the risk of mechanical failures.

Inspection and Adjustment of Components

Regular inspection and adjustment of components are essential to identify and address any signs of wear, misalignment, or damage that may compromise the performance of the extrusion line. Key components such as screws, barrels, heaters, dies, and cooling units should be inspected periodically to ensure proper alignment, tightness, and functionality. Any worn or damaged parts should be promptly replaced or repaired to prevent further deterioration and maintain optimal performance.

Calibration and Alignment

Calibration and alignment are critical maintenance procedures that ensure the accuracy and precision of the extrusion process. Die heads, haul-off units, cutting equipment, and other components should be calibrated and aligned according to manufacturer specifications to ensure uniformity and consistency in product dimensions and properties. Regular calibration checks and adjustments help maintain product quality and minimize variations in output.

Temperature and Pressure Control

Temperature and pressure control are vital aspects of extrusion line maintenance, as deviations in these parameters can affect product quality and performance. Temperature controllers, thermocouples, and pressure gauges should be calibrated regularly to ensure accurate readings and stable control of temperature and pressure throughout the extrusion process. Any fluctuations or deviations should be promptly corrected to prevent defects and ensure consistent product quality.

Preventive Maintenance Schedule

Implementing a preventive maintenance schedule is essential for proactively addressing potential issues and minimizing unplanned downtime. A comprehensive maintenance plan should include regular inspections, lubrication, cleaning, calibration, and component replacement based on manufacturer recommendations and equipment usage. By adhering to a structured maintenance schedule, operators can identify and address minor issues before they escalate into major problems, maximizing equipment uptime and productivity.

Training and Skill Development

Training and skill development are crucial aspects of extrusion line maintenance, as well-trained operators are better equipped to identify, troubleshoot, and resolve maintenance issues effectively. Ongoing training programs, workshops, and hands-on exercises should be provided to operators to enhance their knowledge and skills in equipment maintenance and troubleshooting. Additionally, operators should be encouraged to share best practices and lessons learned to foster a culture of continuous improvement and collaboration.

Conclusion: Maximizing Performance and Reliability

In conclusion, regular maintenance procedures are essential to keep your single wall corrugated extrusion line running smoothly and efficiently. By implementing routine cleaning and lubrication, inspection and adjustment of components, calibration and alignment, temperature and pressure control, preventive maintenance scheduling, and training and skill development, operators can ensure the reliability, performance, and longevity of the extrusion line. By prioritizing maintenance and adherence to best practices, manufacturers can minimize downtime, maximize productivity, and consistently deliver high-quality products to meet customer demands.