Nuts and Bolts: Unraveling the Assembly and Disassembly of Threaded Flanges Compared to Other Flange Types

2024-01-06

Introduction:

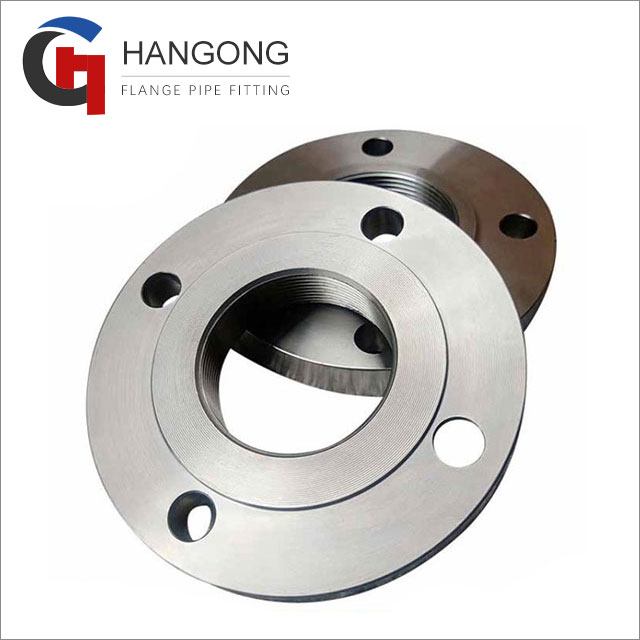

In the intricate world of piping systems, the choice of flanges significantly influences installation, maintenance, and overall system reliability. Threaded flanges stand out for their simplicity and ease of use, but how does their assembly and disassembly process differ from other flange types? In this blog post, we'll unravel the nuts and bolts of threaded flanges, exploring the unique characteristics that set them apart during installation and maintenance.

Assembly Process for Threaded Flanges:

1. Alignment of Threads:

- The assembly of threaded flanges begins with the alignment of the internal threads on the flange with the external threads of the pipe or fitting.

- The threading process, where the threads are cut or rolled onto the flange and pipe, ensures a precise fit.

2. Hand Tightening:

- Threaded flanges are initially hand-tightened onto the pipe, starting the engagement of the threads.

- Hand tightening provides the initial connection and ensures that the threads align smoothly.

3. Torque Application:

- Once hand-tightened, the final tightening is achieved by applying torque to the flange using a wrench.

- The torque applied must be sufficient to create a secure and leak-resistant connection.

4. No Welding Required:

- One of the distinctive features of threaded flanges is that they do not require welding during the assembly process.

- The absence of welding simplifies the installation, making it a quicker and more accessible process.

5. Ease of Adjustment:

- The threaded nature of the connection allows for easy adjustments during the assembly process.

- If necessary, the connection can be easily tightened or loosened to achieve the desired fit.

Disassembly Process for Threaded Flanges:

1. Loosening with a Wrench:

- Disassembly begins by loosening the threaded connection using a wrench.

- The torque applied during the assembly is reversed to loosen the connection.

2. Hand Removal:

- Once loosened, the threaded flange can be hand-removed from the pipe.

- The absence of welding means that disassembly is simpler and does not involve heat-induced processes.

3. Accessibility for Maintenance:

- Threaded flanges offer excellent accessibility for maintenance purposes.

- This ease of disassembly and reassembly is advantageous in applications requiring frequent adjustments or repairs.

Conclusion:

The assembly and disassembly process for threaded flanges distinguishes them from other flange types, primarily due to the absence of welding and the simplicity of threading. The hand-tightening and torque application during assembly, coupled with the ease of adjustment and hand removal during disassembly, contribute to the practicality and accessibility of threaded flanges.

In comparison to other flange types that involve welding, threaded flanges offer a faster and more straightforward installation and maintenance process. This characteristic makes threaded flanges particularly valuable in applications where accessibility, simplicity, and the absence of heat-induced processes are priorities. Engineers and designers can leverage this understanding to make informed choices based on the specific requirements of their piping systems.