Overcoming Challenges in Aluminum Sheet Stamping: Strategies for Success

2024-04-17

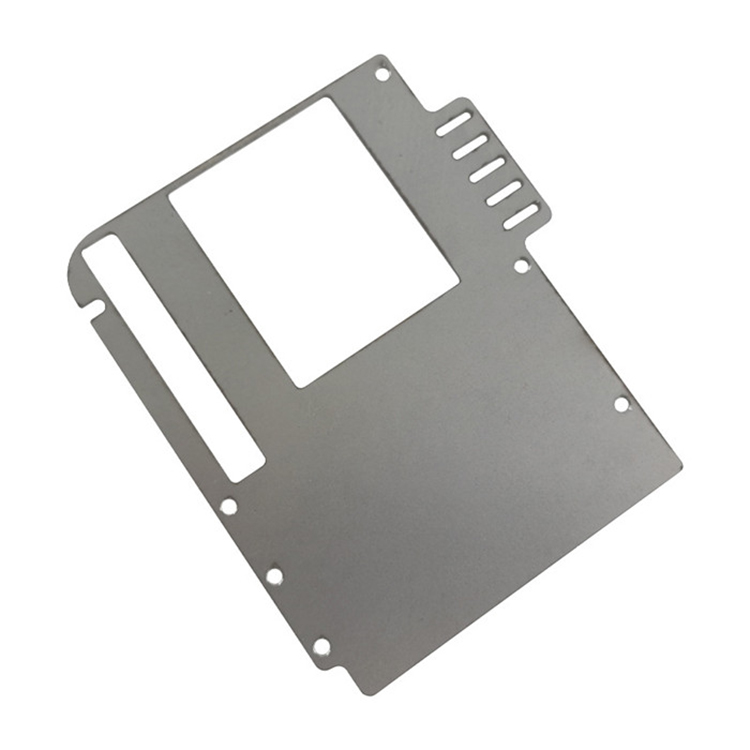

Aluminum sheet stamping is a widely used manufacturing process in industries such as automotive, aerospace, and electronics, where lightweight and durable components are essential. While aluminum offers numerous advantages, including its low density and high strength-to-weight ratio, stamping this material can present certain challenges. In this blog, we'll explore some common challenges or limitations encountered in aluminum sheet stamping and discuss strategies to mitigate them effectively.

1. Material Springback: One of the primary challenges in aluminum sheet stamping is material springback, where the formed part tends to return to its original shape after the stamping process. This can lead to dimensional inaccuracies and affect the final part geometry. To mitigate springback, engineers can optimize tooling design, adjust process parameters such as punch speed and pressure, and employ advanced simulation software to predict and compensate for springback effects.

2. Surface Quality Issues: Aluminum is prone to surface defects such as scratches, dents, and surface cracking during the stamping process. These defects can compromise the part's appearance and functionality. Implementing proper lubrication techniques, using high-quality tooling with smooth surfaces, and optimizing die geometry can help minimize surface quality issues and ensure the production of defect-free parts.

3. Work Hardening: Aluminum alloys tend to work harden during the stamping process, especially in deep drawing operations where the material undergoes significant deformation. Work hardening can increase the material's strength but also make it more prone to cracking and tearing. To address this challenge, manufacturers can use annealing processes to soften the material periodically, reducing its susceptibility to work hardening and improving formability.

4. Edge Cracking: Edge cracking is a common problem in aluminum sheet stamping, particularly in thin-gauge materials or when forming complex shapes with sharp corners. To prevent edge cracking, designers can use fillet radii or rounded corners instead of sharp edges, reduce the clearance between the punch and die, and optimize blank holder force distribution to promote uniform deformation across the part.

5. Die Wear and Maintenance: Aluminum stamping can accelerate die wear due to the material's abrasive nature and tendency to stick to the tooling surface. This can lead to increased downtime for die maintenance and replacement, impacting production efficiency and cost-effectiveness. Employing wear-resistant coatings on die surfaces, implementing proper lubrication and cleaning procedures, and regularly inspecting and maintaining tooling can help extend die life and minimize downtime.

6. Thinning and Wrinkling: Thin-gauge aluminum sheets are susceptible to thinning and wrinkling during stamping, especially in deep drawing operations with high draw ratios. Optimizing process parameters such as blank holder force, lubrication, and drawing speed, as well as using draw beads or pressure pads to control material flow, can help prevent thinning and wrinkling and ensure uniform wall thickness in the formed part.

7. Formability Variations: Different grades and tempers of aluminum alloys exhibit varying levels of formability, which can affect the stamping process and part quality. Conducting material testing and characterization to determine the formability of specific alloys, selecting the appropriate alloy and temper for the application, and adjusting process parameters accordingly can help optimize formability and achieve consistent results in aluminum sheet stamping.

In conclusion, while aluminum sheet stamping offers numerous benefits, it also presents certain challenges that manufacturers must address to ensure successful production. By understanding these challenges and implementing appropriate strategies such as optimizing tooling design, controlling process parameters, and selecting the right material and alloy, manufacturers can overcome limitations and achieve high-quality stamped components efficiently and cost-effectively.