PUR Tubes: Flexible, Durable, and Built for Performance

2025-04-14

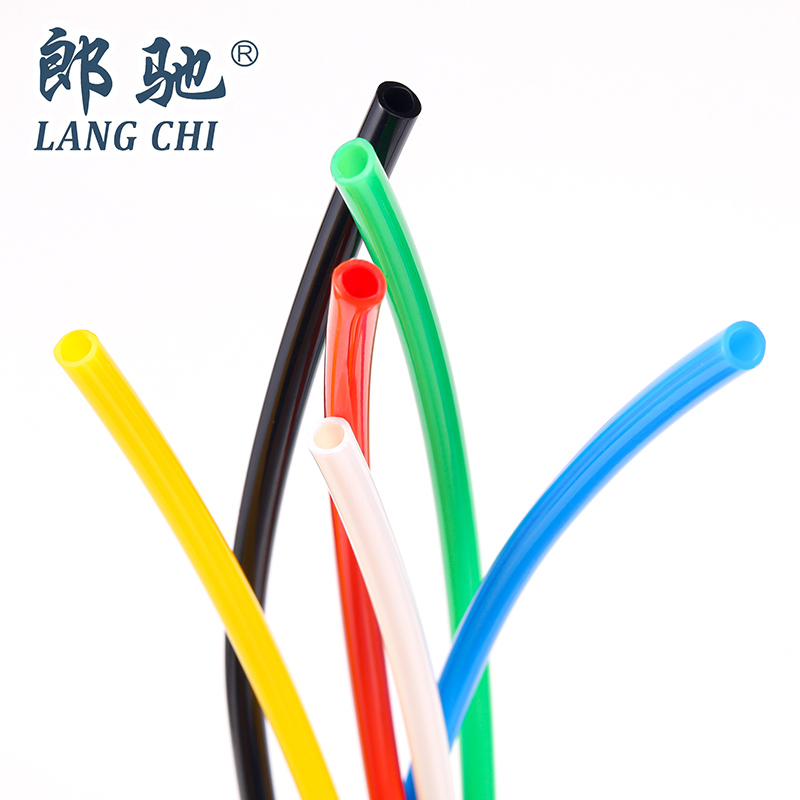

In the world of pneumatic and fluid handling systems, the choice of tubing plays a crucial role in system efficiency, reliability, and longevity. One of the most versatile and high-performing options on the market today is the PUR tube — made from ether-based polyurethane. With excellent flexibility, chemical resistance, and a wide working temperature range, PUR tubing is ideal for applications across various industries, from automation and robotics to water systems and pneumatic tools.

What is PUR Tubing?

PUR (short for Polyurethane) tubing, specifically ether-based polyurethane, is known for its superior resilience and consistent performance. It’s engineered to handle both air and water, making it suitable for a broad spectrum of low-pressure fluid transfer applications.

This material offers excellent mechanical properties while maintaining a high level of flexibility, even in cold environments — a key reason it's widely adopted in industrial automation, automotive systems, and precision machinery.

1. Key Specifications

Here’s a closer look at the technical details that define the quality and performance of the PUR tube:

· Material: Polyether polyurethane

· Fluids supported: Air and water

· Operating temperature range:

· Air: -40℃ to +70℃

· Water: 0℃ to +40℃

· Maximum working pressure (at 20℃): 0.8 MPa

· Hardness range: 85A to 98A

These characteristics make PUR tubing especially suitable for environments where flexibility, low temperature performance, and moderate pressure capacity are required.

2. Sizing and Tolerances

PUR tubes are manufactured with precision tolerances to ensure a secure fit and leak-free operation when paired with compatible fittings:

· Standard outer diameter (OD) options:

· OD 4–12 mm: Tolerance ± 0.1 mm

· OD 14–16 mm: Tolerance ± 0.15 mm

3. Roll Length Options

To accommodate various installation scales, PUR tubing is available in different roll lengths based on outer diameter:

· 200 meters per roll (for OD less than 6 mm)

· 100 meters per roll (for OD more than 8 mm)

This flexibility in packaging allows for efficient use in production lines, service centers, and large-scale installations.

4. Compatible Fittings

For seamless integration, PUR tubing works with a wide range of fittings, including:

· One-touch fittings

· Insert fittings

· Miniature fittings

This compatibility makes it easy to design and maintain fluid systems without the need for specialized connectors or tools.

The ether-based PUR tube is a dependable choice for modern fluid and air transfer systems. It delivers stable pressure performance, excellent flexibility, and outstanding temperature resistance, all in a compact, lightweight form.