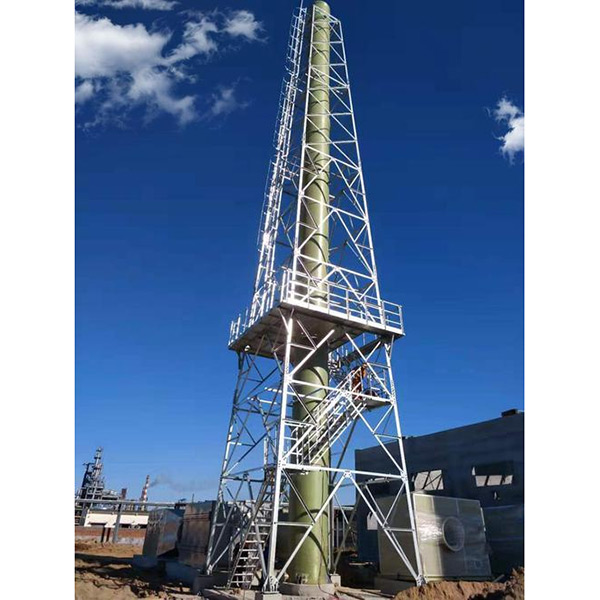

Retrofitting or Replacing Steel Chimneys: Key Considerations for Steel Factory Towers

2024-04-11

In the bustling world of steel manufacturing, where innovation and efficiency reign supreme, the decision to retrofit or replace an existing steel chimney in a factory tower is not taken lightly. It involves careful consideration of various factors, ranging from structural integrity and regulatory compliance to technological advancements and environmental impact. Let's delve into the key factors influencing this critical decision-making process.

1. Structural Integrity and Safety:

The foremost consideration when evaluating the need for retrofitting or replacing a steel chimney is its structural integrity and safety. Over time, exposure to harsh operating conditions, environmental factors, and corrosion can compromise the integrity of the chimney, posing safety risks to personnel and property. Structural assessments, including inspections, load capacity calculations, and material testing, are essential for determining the extent of deterioration and identifying necessary repairs or replacements to ensure the chimney's continued safe operation.

2. Regulatory Compliance:

Compliance with environmental regulations and emissions standards is another critical factor driving decisions related to chimney retrofitting or replacement. As emissions standards evolve and become more stringent, older chimneys may no longer meet regulatory requirements, necessitating upgrades or replacements to ensure compliance. Retrofitting existing chimneys with emission control technologies or replacing them with newer, more efficient designs can help steel manufacturers meet regulatory obligations and minimize environmental impact.

3. Technological Advancements:

Advancements in materials science, construction techniques, and emission control technologies are driving innovation in chimney design and engineering. Newer chimneys may incorporate advanced materials, such as high-strength alloys or corrosion-resistant coatings, to enhance durability and longevity. Integrated emission control systems, such as electrostatic precipitators or catalytic converters, may also be integrated into chimney design to reduce pollutant emissions and improve environmental performance. Evaluating the potential benefits of these technological advancements is essential when considering retrofitting or replacing existing chimneys.

4. Operational Efficiency and Cost-Effectiveness:

Operational efficiency and cost-effectiveness are key considerations for steel manufacturers when deciding whether to retrofit or replace existing chimneys. Retrofitting may offer a more economical solution in cases where minor repairs or upgrades can address performance issues and extend the service life of the chimney. However, if extensive repairs or modifications are required, or if the chimney is nearing the end of its usable life, replacement may be the more cost-effective option in the long term. A thorough cost-benefit analysis, considering factors such as maintenance costs, energy savings, and downtime, is essential for making informed decisions.

5. Future Expansion and Adaptability:

Anticipating future expansion and adaptability is crucial when evaluating the need for chimney retrofitting or replacement. As steel manufacturing operations evolve and grow, existing chimneys must be capable of accommodating increased production capacity and changes in process requirements. Retrofitting existing chimneys to incorporate modular construction techniques or expandable designs may offer greater flexibility and scalability, allowing for future expansion with minimal disruption to operations.

Conclusion:

In the dynamic world of steel manufacturing, the decision to retrofit or replace an existing steel chimney in a factory tower is a multifaceted process that requires careful consideration of various factors. Structural integrity, regulatory compliance, technological advancements, operational efficiency, and future adaptability are among the key considerations that influence this critical decision-making process. By carefully weighing these factors and conducting thorough assessments, steel manufacturers can ensure the continued safety, efficiency, and sustainability of their chimney systems for years to come.