The Role of Double-Sided PET White Film Flexible Circuit Boards in Modern Electronics

2024-09-04

In the ever-evolving landscape of modern electronics, the push for smaller, lighter, and more versatile devices has led to the development of innovative components. One such component is the Double-Sided PET White Film Flexible Circuit Board (FCB). These circuit boards offer a unique blend of flexibility, durability, and efficiency, making them indispensable in a wide range of applications. In this blog, we'll explore the critical role these flexible circuit boards play in modern electronics and how they are shaping the future of technology.

Understanding the Structure of Double-Sided PET White Film FCBs

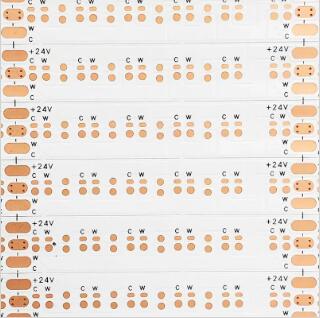

At the core of a Double-Sided PET White Film Flexible Circuit Board is a thin, flexible layer of PET (Polyethylene Terephthalate) film. This film serves as the substrate on which conductive traces are printed on both sides. The "white film" refers to the color of the PET, which is often chosen for its reflective properties, aiding in heat dissipation and improving the visibility of the circuit during assembly.

The dual-sided design allows for more complex circuitry without increasing the board's thickness. This is particularly advantageous in applications where space is limited, and high-density circuit layouts are required.

Why PET? The Advantages of Using PET in Flexible Circuit Boards

1. Thermal Stability

PET offers excellent thermal stability, which is crucial in applications where the circuit board may be exposed to varying temperatures. This stability ensures that the board maintains its structural integrity and performance over time, even under harsh conditions.

2. Moisture Resistance

One of the standout properties of PET is its resistance to moisture. This makes it an ideal choice for applications in environments where humidity or exposure to liquids is a concern, such as in medical devices or outdoor electronics.

3. Chemical Resistance

PET is also resistant to many chemicals, which adds to its durability in industrial applications. This resistance helps prevent degradation of the circuit board when exposed to harsh chemicals, ensuring long-term reliability.

4. Ease of Manufacturing

The use of PET simplifies the manufacturing process due to its ease of handling and ability to be processed using standard industrial equipment. This reduces production costs and speeds up the time-to-market for new products.

Applications That Rely on Double-Sided PET White Film FCBs

1. Consumer Electronics

In the consumer electronics industry, the demand for smaller, thinner, and more powerful devices has driven the adoption of flexible circuit boards. Double-Sided PET White Film FCBs are used in smartphones, tablets, and wearables, where their compact form factor and flexibility are essential.

2. Medical Devices

Medical devices often require flexible, reliable, and biocompatible circuit boards. The moisture resistance and durability of PET make these FCBs ideal for use in medical wearables, diagnostic tools, and implantable devices.

3. Automotive Applications

The automotive industry is increasingly adopting flexible circuit boards to meet the demands of modern vehicle electronics. Double-Sided PET White Film FCBs are used in dashboard displays, sensor systems, and lighting, where their flexibility and resilience to temperature changes are critical.

4. Aerospace and Defense

In aerospace and defense applications, where reliability and weight are paramount, these FCBs are used in various systems, including communication devices, sensors, and control systems. Their lightweight and durable nature helps reduce the overall weight of aircraft and military equipment.

5. Industrial Automation

Industrial automation systems benefit from the compactness and durability of Double-Sided PET White Film FCBs. These boards are used in sensors, controllers, and other automation equipment where space-saving designs are essential.

The Future of Double-Sided PET White Film FCBs

As technology continues to advance, the role of Double-Sided PET White Film Flexible Circuit Boards will only grow in importance. With the rise of the Internet of Things (IoT), wearable technology, and more compact consumer electronics, the need for flexible, durable, and efficient circuit boards is greater than ever.

Emerging trends, such as flexible displays, smart textiles, and advanced medical devices, will further drive the demand for these versatile circuit boards. Additionally, ongoing improvements in PET material technology and manufacturing processes will enhance the performance and cost-effectiveness of these FCBs, making them even more attractive for a broader range of applications.

Challenges and Considerations

Despite their many advantages, there are some challenges associated with the use of Double-Sided PET White Film FCBs:

1. Design Complexity

Designing circuits on a double-sided flexible board requires careful planning to ensure proper alignment and connectivity between the layers. This complexity can increase design time and costs.

2. Mechanical Stress

While PET is flexible, it is still susceptible to mechanical stress, such as bending or twisting beyond its limits. This can lead to potential failure points in the circuit, particularly in applications that require frequent movement.

3. Material Costs

Although PET is more cost-effective than some other materials, the overall cost can increase when factoring in the complexity of double-sided designs and the need for specialized manufacturing processes.

Conclusion

Double-Sided PET White Film Flexible Circuit Boards represent a significant advancement in the field of electronics, offering a unique combination of flexibility, durability, and efficiency. As the demand for more compact and versatile electronic devices continues to rise, these FCBs will play a crucial role in shaping the future of technology. By overcoming the challenges associated with their use and continuing to innovate in their design and manufacturing, the potential applications for these flexible circuit boards are virtually limitless.