Understanding Long-lasting Anti-Static Acrylic Sheets: A Revolutionary Material for Modern Applications

2024-12-17

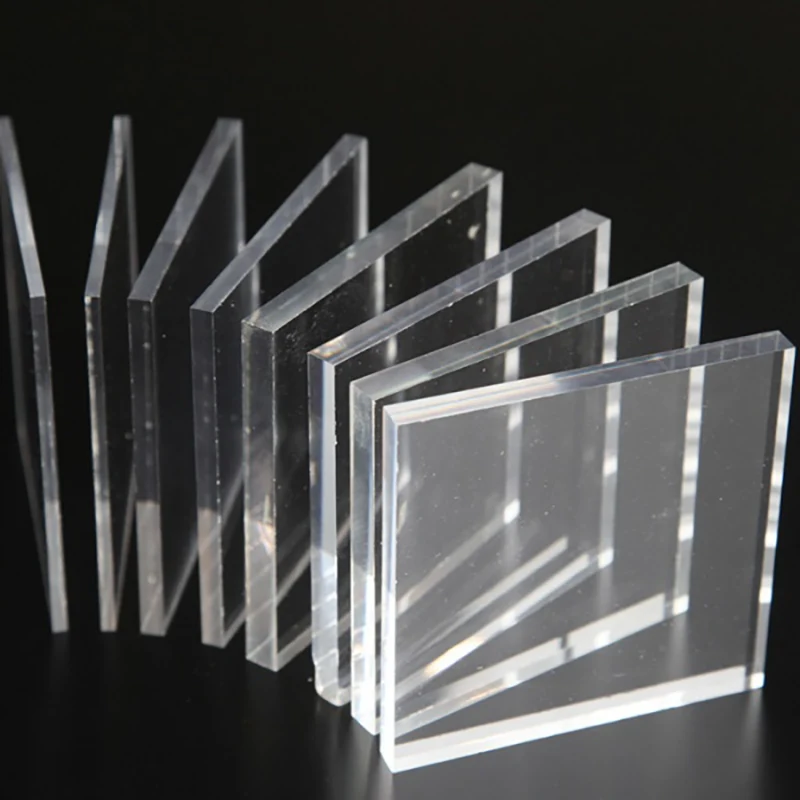

In industries where static electricity poses risks to safety and product integrity, anti-static materials are essential. One such innovation is the long-lasting anti-static acrylic sheet, a material that combines transparency, durability, and electrostatic protection. In this blog, we’ll explore the properties, benefits, and applications of this advanced material and why it’s becoming an industry favorite.

What Are Long-lasting Anti-Static Acrylic Sheets?

Anti-static acrylic sheets are engineered to prevent the build-up of static electricity on their surface. Unlike standard acrylic sheets, these materials are treated with a permanent anti-static coating or are manufactured using additives that ensure long-term electrostatic dissipation.

These sheets retain all the benefits of traditional acrylic—clarity, impact resistance, and lightweight properties—while offering protection against static charges, making them ideal for sensitive environments.

Key Properties of Anti-Static Acrylic Sheets

1. Static Dissipation:

- The anti-static layer maintains surface resistivity between \(10^6\) and \(10^9 \, \Omega/\text{sq}\), which prevents the accumulation of static charges.

2. Optical Clarity:

- The material is highly transparent, allowing for excellent visibility, which is crucial in applications like display covers or cleanroom equipment.

3. Durability:

- Resistant to scratches, impact, and wear, these sheets offer long-lasting performance in demanding environments.

4. Chemical Resistance:

- Anti-static acrylic sheets are resistant to various chemicals, making them suitable for industrial and laboratory settings.

Benefits of Long-lasting Anti-Static Acrylic Sheets

1. Improved Safety:

- By reducing static charge, these sheets help minimize risks such as electrostatic discharge (ESD), which can damage sensitive electronics or ignite flammable materials.

2. Enhanced Productivity:

- In environments like cleanrooms, the anti-static properties help prevent the attraction of dust and particles, ensuring cleaner and more efficient operations.

3. Cost Efficiency:

- Their durability and resistance to wear make these sheets a cost-effective solution over time, reducing the need for frequent replacements.

4. Environmental Stability:

- The anti-static properties are designed to last, even in challenging environmental conditions, maintaining their effectiveness for years.

Applications of Anti-Static Acrylic Sheets

1. Electronics Manufacturing:

- Used as protective covers for equipment or workstations to prevent ESD from damaging sensitive components.

2. Cleanrooms:

- Ideal for partitions, windows, and enclosures, where particle contamination needs to be minimized.

3. Display and Retail:

- Anti-static acrylic sheets are perfect for display cases, preventing dust accumulation while maintaining a sleek, professional appearance.

4. Medical and Laboratory Equipment:

- Widely used in enclosures, panels, and other apparatus where static control is essential for operational precision.

The long-lasting anti-static acrylic sheet is a game-changer for industries requiring transparency, durability, and electrostatic protection. Its versatility makes it a preferred material in cleanrooms, electronics manufacturing, and beyond. If your application demands reliable static control with the durability of acrylic, this innovative material is the ideal solution.